Summary

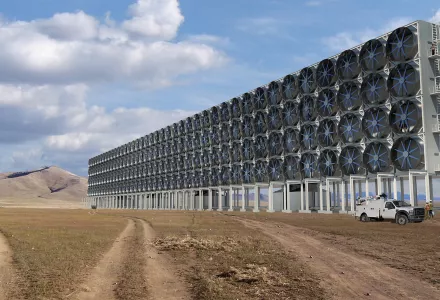

We describe a process for capturing CO2 from the atmosphere in an industrial plant. The design captures ∼1 Mt-CO2/year in a continuous process using an aqueous KOH sorbent coupled to a calcium caustic recovery loop. We describe the design rationale, summarize performance of the major unit operations, and provide a capital cost breakdown developed with an independent consulting engineering firm. We report results from a pilot plant that provides data on performance of the major unit operations. We summarize the energy and material balance computed using an Aspen process simulation. When CO2 is delivered at 15 MPa, the design requires either 8.81 GJ of natural gas, or 5.25 GJ of gas and 366 kWhr of electricity, per ton of CO2 captured. Depending on financial assumptions, energy costs, and the specific choice of inputs and outputs, the levelized cost per ton CO2 captured from the atmosphere ranges from 94 to 232 $/t-CO2.

Keith, David, Geoffrey Holmes, David St. Angelo and Kenton Heidel. "A Process for Capturing CO2 from the Atmosphere." Joule, (2018) .